Clicker dies

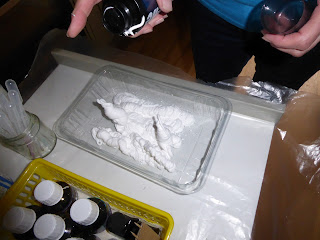

I have always wanted to have a go with a clicker die but had mistakenly thought that I would need a heavy duty press. With time hanging heavy on my hands because of lockdown I thought I would buy a couple of small dies and have a go. I bought one online and while I was waiting for it to arrive stuck together about 8 layers of scrap leathers with PVA to make a pad about an inch thick. The die arrived and I tried it in my bench press but without success and so used a hammer and my scrap pad and gave it a few hefty wallops. That worked OK. The die is mounted in a wooden block and has handy holes to poke through to release the leather. This particular clicker die makes a figure of eight that when folded and linked together forms a strap or lightweight belt. Clickers were the highly skilled people in the shoe factories who cut out the pieces of leather using a metal pattern. As the blade of their knife touched the metal pattern it would click - giving them their name. The left over leather